Creating Custom Built-ins

The Before

When we first moved in, the living/dining room was bare, boring and very yellow, with a long blank wall that did nothing for the space. With the staircase on the opposite wall, and the front door and opening to the kitchen taking up the remaining two walls, the long bare wall needed to do a lot of heavy lifting to carry the design of the room. On that wall, we wanted to add functional storage, artwork, shelves for my collection of books (and Malcolm’s whiskey collection), and an entertainment unit. We also wanted to arrange it in a way that divided the room into distinct living and dining room spaces. The solution we had in mind: custom built-ins.

In This Article:

The Before

Designing Custom Built-ins

Prepping the Space

Building the Boxes

Assembling Custom Built-ins

Adding Lighting

Finishing Touches

The Final Result

Designing Custom Built-ins

After sketching out some possibilities, we settled on a basic design that we were both happy with. It incorporated a gas fireplace in the middle of the wall and two built-in units on either side of it. The fireplace bump out allowed us to conceal some ductwork that we wanted to add. It also helped to act as a divider between the the living room and dining room sides of the room.

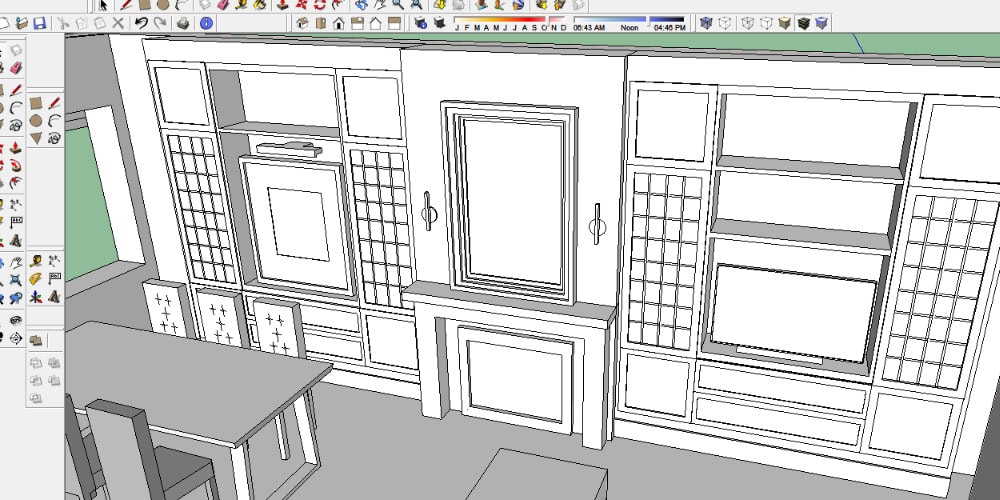

I did the next phase of the design in SketchUp. This allowed us to visualize how the custom built-ins would look in the space. It also provided clear dimensions for us to work from.

This design was partially based around some second hand leaded glass panels I salvaged. (As of now, we still have yet to put in these panels, but maybe one day).

Creating the design in 3D also allowed me to identify some opportunities as well as obstacles. The detailed design was a reminder that the units could not extend the full length of the wall because of the window on the perpendicular wall; if the unit ran too close to the corner, it would overlap the window. The 3D SketchUp design allowed me to play with those dimensions and see how far we would have to bring the units in from the corners of the room in order to keep the leftover space in the corners feeling intentional and functional.

Drawing out the details also allowed me to see that lighting would be something we would want to incorporate into the units, as well as the fireplace in the center. This meant that we would need to run the electrical ahead of time, and consider where the switch to control that lighting would be located.

If you are planning on designing your own custom built-ins, I would recommend thinking about whether you want to incorporate lighting early on, so that you can plan for it before you have constructed the unit, and put it in place.

Prepping the Space

Putting fresh drywall on the ceiling allowed us to cover up the existing popcorn texture and drop part of the ceiling to make it level. I also ran two electrical cables up through the ceiling to come out within the vicinity of the living room built-in unit so the switch near the front door could control some LED lighting in the built in, as well as the fireplace sconces.

The electrical for the art light on the dining room side was diverted directly from an outlet that was being displaced by the built-in, so we added a light junction box for that, as well as relocating a couple outlet boxes on the living room side that could be used for the entertainment unit.

Building the Boxes

To build the boxes, we used medium-density fiberboard. MDF is a cost effective material, but not the most durable. Screws going into it are not as secure as they are in solid wood or plywood because the fibers on MDF can become loose if overworked, so it is important to always use wood glue when joining the pieces. It is also much more susceptible to moisture damage and can swell if wet, so it should be sealed with a good latex paint at the end. While the MDF worked fine in this case, I think if we were to build custom built-ins again, I would opt for plywood.

The pieces were joined using regular wood glue and pocket screws (1-1/4″). These corner clamps came in handy to ensure each corner dried at 90 degrees without slipping.

Each built-in unit was large, so we built the boxes in sections so we could carry them up from our basement workshop and assemble them in place. Each unit was comprised of five pieces: two of the tall side cabinets; two of the horizontal boxes, each divided into four sections; and the large middle square.

We also added a sheet of 1/8″ plywood to the back of each box, instead of relying on the existing wall to be a backing to the unit. This was because the existing wall wasn’t the most even or plumb, so this allowed the boxes to be enclosed at the back, with no gaps for things to fall behind.

Assembling Custom Built-ins

For the base of the unit, we built it to the desired height using 2x4s and made sure it was properly supported, level and plumb. Then, we set the long 4-section bottom box on top of the base frame and built up the pieces from there, gluing them together using wood glue, and using clamps to hold them until the glue dried. A few finishing nails were used to hold the pieces together, and some screws where they wouldn’t be visible (like where the drawers would eventually go) but because we wanted to keep the inside free of holes as much as possible, we mostly relied on the glue for this part.

Adding Lighting

The next stage was adding the LED lighting. We used dimmable linking LED puck lights in warm white. These were direct wired so that we could control the lighting from the switch near the front door, however, there are many types of puck lighting available that can be plugged into an outlet and controlled using a remote control.

The lights we chose did come with a remote control that we can use to adjust the brightness (and make them blink if that’s something we wanted). We also made sure to choose lighting that linked in a series, not in parallel, so we could daisy-chain them starting from the power source, eventually connecting to the unit on the other side of the fireplace so that one switch would turn on the lighting on both built-in units at once.

Finishing Touches

To cover up the joints in the MDF, we used 1/8″ strips of poplar, 1-1/2″ wide to trim out the front of the units. On the base, to cover up the 2x4s, we fitted a piece of MDF to fill the gap beneath the bottom set of boxes. To that we attached baseboard trim that matched in with the rest of the baseboard in the room.

At the top of the units, we first placed some blocking to attach the upper trim to. Like the bottom, we first attached a fitted piece of MDF that extended up to the ceiling, providing a solid base to secure the crown molding to.

Next came the filling and painting. I used a latex filler in gray to fill the holes from the face trim, bottom baseboard and the gap between the bottom of the baseboard and the floor. Then I used a high-quality furniture paint in a soft gloss finish to paint the units, including the baseboard. Two coats of this paint provided the perfect coverage without primer, and in my experience, selecting a high-quality paint is always worth the extra $10 or $20 because of the time it saves and the quality of the end result.

For a while, we kept the unit as open shelving while we focused on other projects in the house. To be honest, at that point in our DIY experience, the idea of making and fitting the drawers and cabinet doors felt a bit daunting and we had a hundred other projects that were taking precedence over finishing the final stage of the built-ins.

So full disclosure, we ended up enlisting the help of one of our friends who makes cabinetry to help us with the doors and drawers. Although part of me felt like we were giving up on a challenge by turning to someone else to do this last part, the final result tuned out great, and when we watched him meticulously fit the drawers so that the gap was perfectly even between the drawer faces, I knew we had made the right choice.

The Final Result

Creating custom built-in units can transform not only the look of a space, but the way you use it. It is so useful having additional storage in the room where we spend the most time. And in a small space, having drawers to keep things like our son’s daycare clothes adds a bit of convenience to each day.

Actually, these units are not quite finished; there is currently no glass in the cabinet doors (that’s not just really clean glass you’re looking at), and I’m still holding out hope for the day I have the time to fix up the leaded-glass panes to put inside. So stay tuned.

Still, we are extremely happy with the result and I would highly recommend trying this project out for yourself if this is something you think might add functionality to your space. There are so many ways to build the boxes (it doesn’t have to be from scratch!) I have seen many inventive built-ins being retrofitted from Ikea storage and other off-the-shelf cabinetry, and these days, there are so many good tutorials available online for making building projects even easier.

Since making these units, I have seen numerous videos about making the drawers boxes and door/drawer fronts from scratch that make me think that we definitely could have managed that part of the build, had we devoted the time to it. This is definitely something I would love to accomplish on future projects and I know the opportunity for another custom built-in is just around the corner.